TINKER AIR FORCE BASE, Okla. —

The 448th Provide Chain Administration Wing, a part of the Air Power Sustainment Heart, has a brand new additive manufacturing method to resolve an outdated downside, sourcing exhausting to amass components for legacy plane.

By digitally recreating the mould used to create forged components, as a substitute of constructing the half from scratch, the Strategic Alternate Sourcing Program Workplace can work with distributors to provide components sooner whereas saving the Air Power cash.

“We’re looking for methods to get the low-quantity components sooner,” mentioned Loren Lutz, Air Power Life Cycle Administration propulsion chief engineer. “We’re supporting a big variety of outdated platforms and we’re going to hold supporting them for a very long time. We now have to determine find out how to get the components we want. Something that we will do technically to make that doable after which work with our companions on the provision chain facet to have the ability to go purchase them is actually useful.”

Additive manufacturing has been a specialty of Tinker Air Power Base’s Reverse Engineering and Crucial Tooling Lab, often known as REACT, for various years. Nevertheless, the dimensions and complexity of sure components don’t lend themselves to present 3D-printing strategies the place the half is constructed from scratch. Even when the half had been to be recreated on this technique, the half can be topic to prolonged airworthiness testing earlier than it could be allowed to fly.

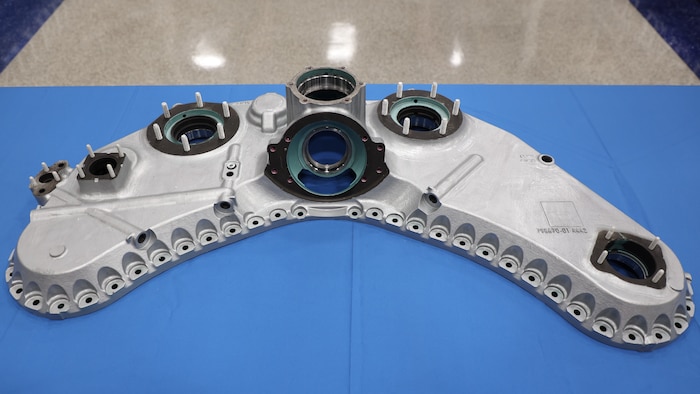

Such is the case with the rear gearbox housing for a TF33 jet engine. Produced from magnesium, the housing was initially produced by casting – pouring molten metallic right into a mould then milling the half to provide a closing product. The mould used to create the half is also called a tough software and is mostly constituted of excessive energy metal.

Variants of the TF33 energy plane such because the B-52H Stratofortress, E-3 Sentry and E-8 JSTARS. As these legacy plane proceed to fly, components that weren’t anticipated to wear down are coming due for alternative.

“If we haven’t purchased this half for 20 or 30 years, we don’t have the exhausting tooling anymore; the unique gear producers, the distributors, they don’t have it,” mentioned Randolph Harris, 429th Provide Chain Administration Squadron OTA program supervisor. “That’s why it takes 900 days or extra to get these components, as a result of they’re going to spend the primary 18-24 months simply recreating the exhausting tooling.”

Including to the issue is the truth that many components will solely be wanted in small numbers, leading to many distributors opting to “no bid” on a contract.

The pathfinder challenge to deal with these issues started in 2019, exploring using additive manufacturing to deal with the challenges in securing forged components.

Utilizing the precise half as a information, new digital molds had been created. In comparison with the unique, the ensuing components are correct to a thousandth of a millimeter. Even the raised lettering on an oil inlet port is similar.

The time it took to develop the brand new course of and construct a prototype was truly shorter than the manufacturing lead time the gearbox housing would have required had it been produced utilizing conventional strategies.

“What we’re truly getting out of this course of is the complete drawing package deal of the way you make the half,” mentioned Lutz. “It’s the casting drawing, manufacturing drawing and the ultimate half drawing; it’s all the pieces you would want to go make the half, which is a deeper degree of data than we’ve got on our components which present up from the OEMs.”

With the digital blueprints in hand, a sand mould to forged the half was created. The sand mould is destroyed within the manufacturing course of however may be simply recreated the subsequent time an element is required. What usually took greater than 900 days can now be achieved in 30-60 days.

“We did make the most of additive manufacturing on this course of, nevertheless we don’t need to do any configuration management board, we don’t need to do any airworthiness, except the engineer tells me totally different, as a result of this half is produced precisely just like the half we have already got put in,” Harris mentioned. “What we did in another way is Renaissance Providers, Inc. developed the method, and we took out the exhausting tooling, additively manufacturing the mould.”

As a result of the Air Power owns the ensuing mental property, it may be taken to different distributors for manufacturing reasonably than being tied to 1 producer. The half may be manufactured internally, making the scenario rather more aggressive with a excessive potential for value financial savings.

Castings are the place the challenge began, but it surely is not going to be the place it ends. One of many SASPO Workplace’s main missions is to match up Air Power necessities with suppliers who might help maintain the fleet.